PET Bottle Flake Granulation Line

PET Botolo Yobwezeretsanso Pelletizer PET Granulation Machine Njira ikuyenda

Kufotokozera zaukadaulo

|

Dzina la Makina |

PET Single Screw Extrusion pelletizing Line |

|

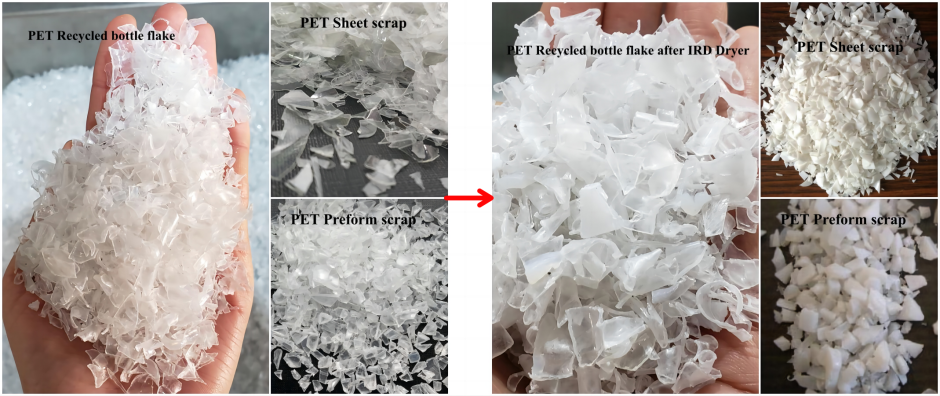

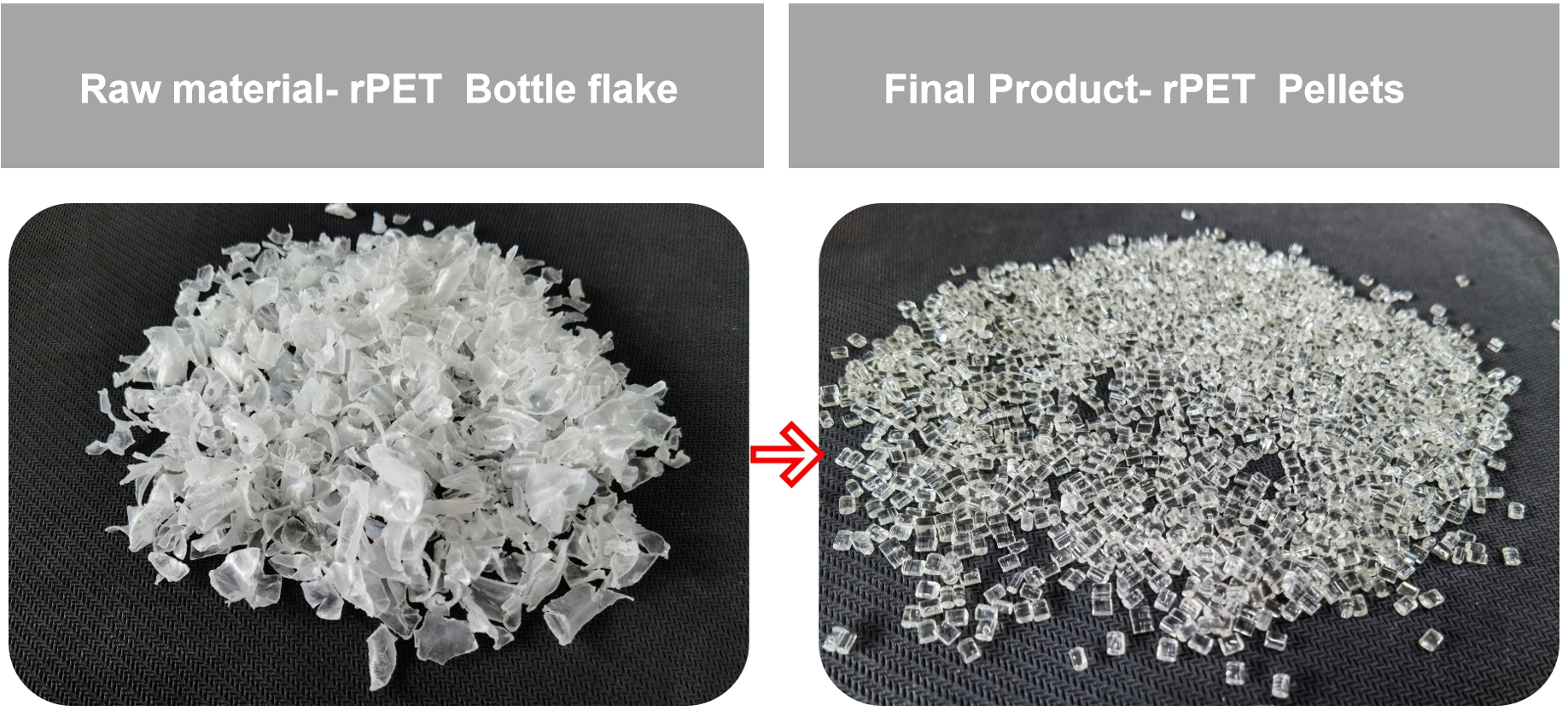

Zopangira |

rPET Flakes |

|

Chomaliza Chomaliza |

rPET Pellets |

|

Zida Zopanga Line | Infrared crystal dryer system: Vacuum feeder/ Chowumitsira kristalo cha infrared/ Chotupitsa

Mzere umodzi wokhotakhota wa Single Screw Extrusion: Single screw main extruder/Hydraulic Double Pistons screen chosinthira/Die mutu/Flushing water ththth/Flushing pellitizer/Vertical dewatering machine/Vibrating sieve machine/ yosungirako

|

|

Screw diameter |

90mm-150mm |

|

L/D |

1:24/1:30 |

|

Zotulutsa |

150-1000KG/H |

|

Zomangira |

38CrMoAlA yokhala ndi Chithandizo cha Nitrding |

|

Pelletizing Type |

Kuthamanga kwa madzi & pelletizing |

|

Kusintha skrini |

Hydraulic Double Pistons Screen Changer |

Zambiri zamakina

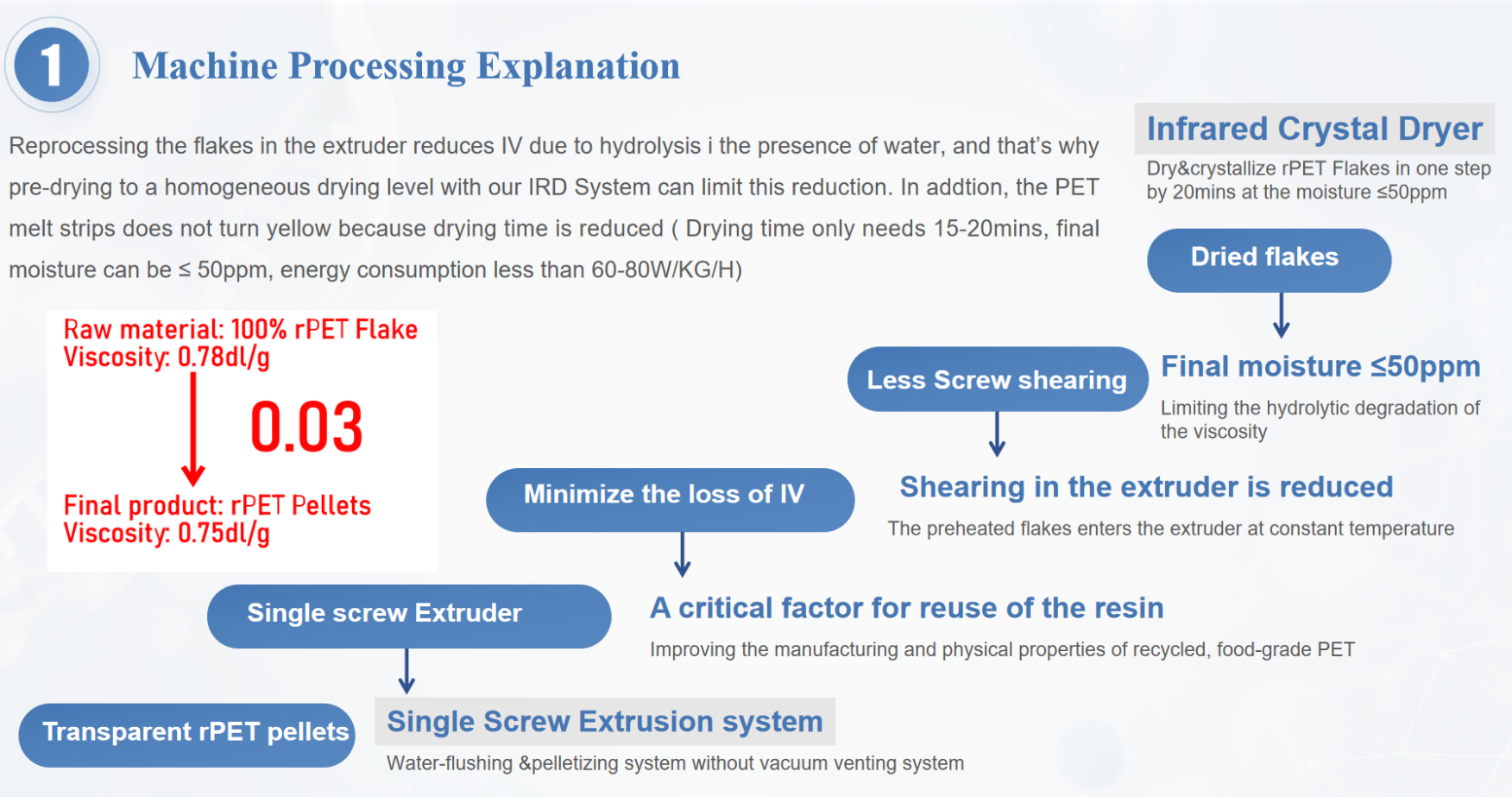

Infrared Crystal Dryer (LIANDA PATENT DESIGN)

①Kupititsa patsogolo kupanga ndi mawonekedwe azinthu zobwezerezedwanso, chakudya cha PET kudzera muukadaulo woyendetsedwa ndi mafunde a infrared kuli ndi gawo lofunikira pochita nawo gawo la intrinsic viscosity (IV)

②Pre-crystallization & kuyanika kwa flakes isanatulutsidwe kumathandizira kuchepetsa kutayika kwa IV kuchokera ku PET, chinthu chofunikira kwambiri kuti mugwiritsenso ntchito utomoni.

③Kukonzanso ma flakes mu extruder kumachepetsa IV chifukwa cha hydrolysis pamaso pa madzi, ndichifukwa chake kuyanika kusanachitike kuyanika kofanana ndi IRD System kumatha kuchepetsa kuchepa uku.

Kuonjezera apo, mapepala a PET asungunuke sasanduka achikasu chifukwa nthawi yowumitsa imachepetsedwa ( Kuwumitsa nthawi kumangofunika 15-20mins, chinyezi chomaliza chikhoza kukhala ≤ 30ppm, kugwiritsa ntchito mphamvu zosakwana 60-80W / KG / H)

④Kumeta ubweya mu extruder kumachepetsedwanso chifukwa zinthu zomwe zimatenthedwa kale zimalowa mu extruder ndi kutentha kosalekeza”

⑤Kupititsa patsogolo kutulutsa kwa PET Extruder

Kuwonjezeka kwa kachulukidwe kochuluka ndi 10 mpaka 20 % kumatha kupezedwa mu IRD, kumapangitsa kuti chakudya chiziyenda bwino polowera kwambiri - pomwe liwiro la extruder silinasinthe, pamakhala kudzaza bwino kwambiri pa screw.

Single Screw Extrusion Pelletizing Line (Popanda Vuto Lopuma)

Pogwiritsa ntchito mphamvu za Single screw extruder ndikuyiyika ndi LIANDA zopangira mwapadera zopangira ma rPET Bottle flakes, tidatha kuwonjezera mphamvu ndi 20% ndi mphamvu zochepa zomwe zimagwiritsidwa ntchito poyerekeza ndi Parallel double screw extruder.

Viscosity ya ma pellets a rPET opangidwa ndi dongosolo lathu: pali ≤0.02-0.03dl/g kutsika kwa viscosity yokha ---popanda kuwonjezera kukhuthala kulikonse. (Malinga ndi kuyesa kwathu m'nyumba)

Mtundu wa ma pellets a rPET: wowonekera --- osawonjezera chowonjezera chilichonse

Popanda Vacuum venting system --- Kupulumutsa mtengo wamagetsi, ntchito yopanda mavuto komanso yokhazikika

Zithunzi za Makina